MAJOR ACHIEVEMENTS

Discover our major achievements and how TheCrossProduct has become a reference for many significant players in industrials fields.

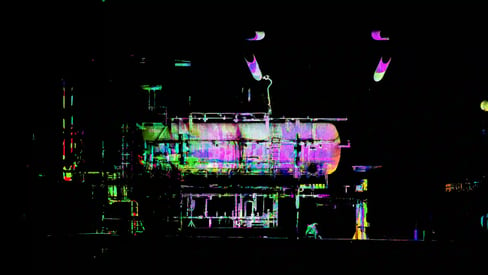

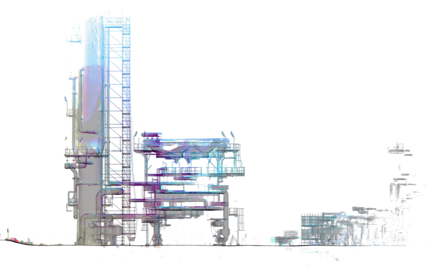

A Revolution in the Quality Check of 3D LiDAR data

This is where TheCrossProduct came in. Armed with our expertise in 3D LiDAR data processing, we worked closely with Total Energies teams to design a tailor-made solution: automatic quality check software, specially designed to meet their unique needs.

Our software, "Quality Check", is based on advanced algorithms that automatically detect and report potential anomalies in point clouds. Whether it is checking the density of point clouds, the registration of scans, or identifying the presence of noise, this tool is able to review massive volumes of data in record time. Thanks to this automation, the verification process has gone from several days of manual work to a fast and reliable analysis, thus eliminating uncertainties and human bias. The deliverable is in the form of an analysis report mentioning the type of non-conformity and the attached scan.

The deployment of this solution has been particularly appreciated within the Geospatial department of Total Energies. Their ability to guarantee the exploitation of high-quality LiDAR scans has never been so efficient! Not only has the processing time been drastically reduced, but the savings made in operating costs are significant.

Today, Total Energies has found the solution to the problem of verifying the conformity of its acquisitions and encourages TheCrossProduct to develop other solutions of this type that meet a clear need. The return on investment is undeniable: an optimization of time, a considerable reduction in costs, and an almost total elimination of the risks of human error and above all an effective response to a technical problem. Technical teams are now freed from the chore of tedious verifications to focus on tasks with high added value.

With this example, TheCrossProduct once again demonstrates its ability to resolve complex problems using cutting-edge technological solutions, adapted to the real needs of its customers.Problem

Checking the quality and conformity of each point cloud manually is time-consuming and prone to human error.

Solution

Development of custom automated software capable of checking the conformity of thousands of scans.

Results

Analysis report of all scans not meeting compliance fields.

ROI

2x cheaper, 10x faster, 100% reliable

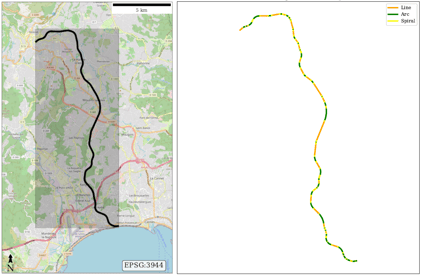

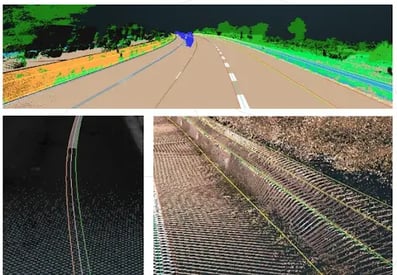

European Railway Revolution: Automated Track Geometry Analysis

The Marseille - Ventimiglia railway line, a strategic axis of cross-border mobility, presented major technical challenges. Until now, the track geometry was carried out manually, an extremely time-consuming and unsustainable method to meet the deadlines set by the ERTMS project. Furthermore, this analysis requires specific savoir-faire from railway track experts, who are rarely available.

Analyzing, modeling and validating the plan axis and the longitudinal profiles required months, even years of work, delaying critical decision-making and increasing costs.

It is in this context of technical and technological challenge that TheCrossProduct has developed an innovative automated software to analyze the geometry of railway track axis, capable of generating precise models of horizontal and vertical alignments in both plan and profile views in just a few minutes. Thanks to this cutting-edge technology, the complete layout of the Cannes-Grasse line, pilot line of the HPMV (High Performance Marseille Vintimille) project, was able to be modeled quickly, providing files in the standardized LandXML format. An exceptional time saving: Where previously several weeks of manual work were required, TheCrossProduct's solution performs the same task in a few minutes.

This solution not only reproduces the railway layout: it also allows for the instant identification of existing non-conformities and defects. Engineers can thus analyse the data at a glance, significantly reducing diagnostic and intervention times.

SNCF Réseau is more than won over by the results obtained. Thanks to TheCrossProduct, it has a strategic tool to achieve its modernization and compliance objectives. The collaboration has been a real success, consolidating a relationship of trust and paving the way for new innovative projects...

This project is much more than a national success story. It demonstrates how the technologies developed by TheCrossProduct can be deployed on a European scale to support sustainable mobility and accelerate the adoption of ERTMS. By making automated geometry analysis of the track applicable on a large scale, feasible within controlled timeframes, while being more cost-effective, this project lays the foundations for a structural transformation of the European railway network.

With this project, TheCrossProduct asserts its leading position in railway geometry and contributes to shaping the future of rail mobility in Europe.

Problem

Rediscover the railway track geometry analysis of hundreds of kilometers

Solution

Development of automated track geometry analysis software, plan axis and longitudinal profile generated in a few minutes.

Results

Plan axis and longitudinal profiles in standardized LandXML format.

ROI

Projects of hundreds of km achievable, 100x faster, precision of results

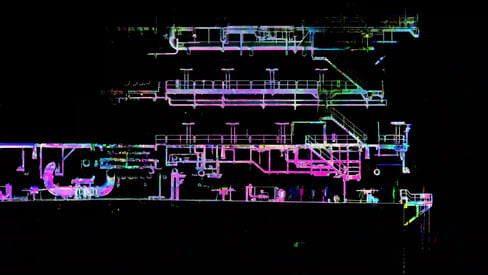

ARA Project - An exemplary collaboration between TheCrossProduct and the setec group

For many years, TheCrossProduct and the setec international digital hub have been working together on major projects in the highway and railway sectors. This relationship of trust and synergy has enabled significant progress to be made in the modernization of infrastructure, combining technological expertise and high-precision engineering.

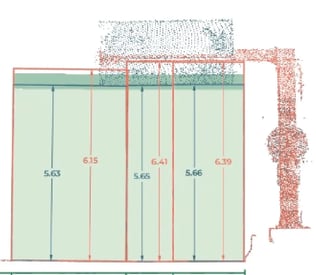

The ARA - Automated Road Analysis - highway project perfectly illustrates this collaborative dynamic, with remarkable results in terms of efficiency, precision and return on investment (ROI).

A distribution of strategic skills

The ARA project was structured into two key stages which highlight the complementary expertise between TheCrossProduct and setec:

- 3D data extraction and point cloud analysis by TheCrossProduct

TCP took charge of the first crucial step of the project: the extraction and automated processing of data from 3D point clouds. TheCrossProduct’s expertise in this field made it possible to achieve:

- High-precision measurements and modeling, including track widths, platform slopes, safety barriers;

- A reverse engineering of the road axis alignments : horizontal and vertical alignements have been automatically computed

- Precise gauge studies to check the heights under structures and gantries;

- Road engineering analysis and compliance by setec international

Armed with the data extracted by TheCrossProduct, setec teams took over to conduct the essential engineering analyses, including:

- The study of the conformity of the infrastructure to the standards in force;

- Identification of adaptations needed to improve safety and efficiency;

- A detailed view of the state of the infrastructure and the interventions to be considered.

A complete file for informed decisions

At the end of the project, a complete file was produced. This deliverable brings together all the elements necessary for optimized decision-making: precise 3D models, compliance studies, detailed diagnostics and intervention recommendations. This high-quality work thus allows the highway manager to have all the keys to make optimal decision-making.

An essential ROI thanks to TheCrossProduct

TheCrossProduct’s involvement in the automated processing of 3D point clouds played a decisive role in the success of the project. By offering advanced technological solutions, TheCrossProduct made it possible to:

- Accelerate the project by significantly reducing data processing and analysis times;

- Guarantee incomparable precision of the results obtained, essential for engineering analysis;

- Optimize costs through automation of processing and reliability of the data provided.

A winning collaboration

The ARA project is proof that when TheCrossProduct and setec combine their expertise, the results are as expected. Their long-term collaboration on complex projects not only allows for greater efficiency, but also ensures an exceptional level of quality.

This success reaffirms TheCrossProduct’s position as a key player in the exploitation of 3D LiDAR data for infrastructure projects and underlines the importance of synergies between advanced technologies and traditional engineering.

Problem

Traditional methods are unsuitable for the geometric study of large road networks because they are time-consuming, subject to human error, and inapplicable to large-scale projects.

Solution

Our automated software is capable of performing massive data analysis with precision. Combined with the business expertise of an engineering company, our software offers a turnkey solution to highway concessionaires for fast and informed decision-making.

Results

Measurements, 3D modeling, template studies, reverse engineering, conformity analyses, recommendations, etc.

ROI

Large-scale analysis, time saving (10x faster), higher accuracy (x10 more accurate)

Revolution in Road Reverse Engineering: TheCrossProduct x Geograma

The world of road infrastructure is changing, and at the heart of this transformation is a pioneering collaboration between TheCrossProduct and Geograma. Together, we are taking on a challenge of enormous magnitude: to reverse engineer Spain’s roads, covering thousands of kilometers, using a revolutionary technological approach..

A challenge on a very large scale

Spain has one of the most extensive road networks in Europe, connecting cities, towns and rural areas. However, the management, maintenance and optimization of this vast network requires precise data on the geometry of the roads: the horizontal and vertical alignments, lanes width and slope, and other essential characteristics. This information, fundamental for planning and maintenance works, is usually obtained through a manual reverse engineering process.

Until now, this task has been exasperatingly slow. A route expert can only handle a maximum of a few kilometers of road per day. When faced with thousands of kilometers, this represents months, if not years of work. A radically more efficient solution is needed!

Automated Reverse Engineering by TheCrossProduct

TheCrossProduct, recognized for its expertise in automated processing of 3D LiDAR data in highway and railway environments, provides an automated reverse engineering solution for the needs of Geograma and Spanish roads…

Thanks to a powerful algorithm combining machine learning and high-precision geometric analysis, our software is capable of:

- Automatically calculate the horizontal and vertical alignments of a road network from the road axis.

- Deliver results with unmatched accuracy, even on roads with complex alignments.

- To accomplish this titanic task in just a few minutes, where entire days were previously required.

A Technological and Technical Revolution

This project is more than just a productivity improvement. It is a revolutionary step forward for the road infrastructure sector. By solving the technological challenge of automating large-scale road reverse engineering, TheCrossProduct opens up new possibilities:

- Considerable Time Savings

Thousands of miles of roads can now be analyzed in days, instead of years. - Operations optimization

The time saved on the reverse engineering part allows the layout experts to concentrate more on the analysis and recommendation part, in order to optimize operations. - Exceptional Precision

The technology ensures accurate and reliable results, essential for strategic infrastructure decisions. - Scalability

This technology is the solution to the problem of large-scale projects, which were previously impossible to carry out. The solution can be adapted to other major road networks, offering opportunities on a global scale.

Concrete Results

For Geograma, the results speak for themselves. With TheCrossProduct solution, they can:

- Drastically speed up their processes.

- To provide their customers with comprehensive geometric data of unmatched quality.

- Positioning ourselves as leaders in the analysis of road infrastructures in Spain.

The collaboration between TheCrossProduct and Geograma is proof that 3D LiDAR technology and business expertise can drastically improve infrastructure management. By automating a crucial process on a large scale, TheCrossProduct has once again demonstrated its role as a technology leader, paving the way for a future where road infrastructure management will be smarter, faster and more efficient.

Problem

Manual reverse engineering of thousands of kilometers of roads in Spain. Time consuming and prone to human error.

Solution

TCP's automated reverse engineering solution, capable of processing massive data accurately and in minutes.

Results

Road geometry, plan axis and longitudinal profile generated in minutes...

ROI

Save time and get accurate results